When erection demands exceptional strength and durability, wire mesh emerges as a vital component. Its intricate woven pattern provides unparalleled resistance, ensuring the integrity of various applications. From reinforcing concrete to forming protective barriers, wire mesh offers a versatile and reliable solution for diverse engineering needs.

Its compact nature and ease of deployment further boost its appeal in construction projects. Whether used in walls, floors, or ceilings, wire mesh effectively redistributes loads, mitigating stress on underlying structures. This superior functionality makes wire mesh a preferred choice for professionals seeking to provide structural integrity and long-lasting durability.

WY Mesh: Weaving Strength and Design

WY Mesh is revolutionizing the sector with its innovative approach to strength. This cutting-edge mesh technology seamlessly combines artistic appeal with exceptional effectiveness. Whether it's for structural applications, WY Mesh provides a adaptable solution that meets the most demanding demands. Its unique weave pattern not only guarantees superior strength but also creates an sophisticated design element.

- Enhancing the aesthetic appeal of buildings and structures

- Delivering exceptional durability in challenging environments

- Meeting diverse design requirements with its customizable options

Wire Mesh Applications: From Construction to Art

Wire mesh offers a surprisingly extensive range of applications, extending far beyond its website traditional role in construction and infrastructure. While it remains a crucial component for reinforcing concrete structures, fencing, and sieving materials, wire mesh has also emerged as an innovative material in the realm of art and design. Artists employ the inherent texture and strength of wire mesh to create intricate sculptures,wall installations, and even wearable pieces. The malleability of wire mesh allows for free-form shapes, while its open structure creates a sense of airiness. From utilitarian applications to artistic expressions, wire mesh continues to transform as a adaptable material that bridges the gap between practicality and creativity.

Wire Mesh: A Versatile Material

Wire mesh is a incredibly versatile material with a wide range of applications. Its strength and flexibility make it an ideal choice for countless tasks. From construction, to filtration, wire mesh plays a vital role in our daily lives. Whether you need a durable barrier or a precise screen, there is a kind of wire mesh to satisfy your specific needs.

- Many common uses for wire mesh include:

- Construction: Reinforcing concrete, creating protective barriers

- Manufacturing: Conveying materials, protecting equipment

- Farming: Protecting crops from pests, making animal cages

- Purification: Removing impurities from liquids or gases

With its extensive range of sizes, materials, and coatings, wire mesh can be customized to meet a vast array of requirements. So, the next time you need a durable solution, consider the versatility of wire mesh.

Understanding Wire Mesh: Types, Properties, and Uses

Wire mesh, a versatile commodity, is comprised of interwoven wires, forming a rigid lattice-like structure. This framework exhibits remarkable characteristics making it suitable for a wide range of applications.

Common types of wire mesh include welded mesh, plain mesh, and screened mesh, each possessing distinct qualities.

Its sturdiness allows it to resist heavy loads and impacts.

Furthermore, wire mesh is lightweight and oxide-resistant. Applications for wire mesh are numerous, ranging from construction to separation. It can be used in boundary delineation, industrialsieves, and even in the clinical field for wound care and support.

Understanding the different types, properties, and uses of wire mesh is crucial for selecting the appropriate material for specific needs.

Pros of Wire Mesh in Modern Engineering

Wire mesh has become an indispensable tool in modern engineering. Its adaptability facilitates a diverse array of applications, from construction to production.

Additionally, wire mesh is renowned for its robustness, making it ideal for demanding conditions.

Its open structure facilitates superior ventilation, while its compact nature streamlines assembly.

Ultimately, wire mesh offers a cost-effective and dependable solution for countless engineering challenges.

Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Phoebe Cates Then & Now!

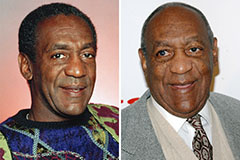

Phoebe Cates Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!